Shoki II-otsu 2

6/Feb/2009

|

|

|

All rivet lines were determined from the photos of the actual A/C not from drawings. |

Kit's panel lines were a little different. Pencil lines are correct. |

|

|

I tested these glues. |

|

|

First of all, the panel near horizontal fin was glued. Next, the right side panel was attached followed by the lower narrow panel. |

The panels were held in position with scotch tape until the glue hardened. |

The annealed aluminum sheet can be formed very well even on the tight curves such as the wing root fillet. |

It was glued on the fuselage. |

The leading edge of tail fin was formed like this. |

Excess glue presented no problem as it was sanded down after it set. |

The surface was sanded with 320 grit sanding paper. |

The surface was finished with 600 grit sanding paper. |

|

|

The aluminum work is suitable for mobile modeling. Tools and materials could be stored in this small box and carried easily. |

|

|

The upper outline of supercharger air intake was corrected. The plastic sheet was glued and sanded. |

The outline is bent at the point of the panel line. |

|

The diameter of the cowling leading edge became shorter by about 0.5mm caused by the thickness of aluminum sheet. The leading edge should be enlarged before gluing the aluminum sheet. |

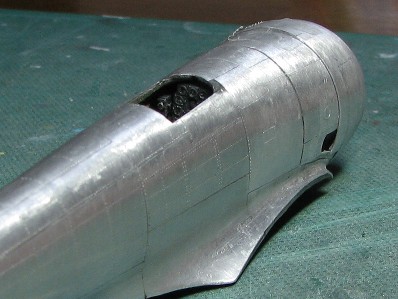

The air intake was enlarged to upwards. Then the shape was improved. Some of the kit's panel lines were corrected. |

I drilled out the gun openings, engraved cowl flaps and made the cut-out for the exhaust. |

|

|

The starboard fuselage was done. After the surface was sanded, wash was applied using Tamiya Weathering Master. |

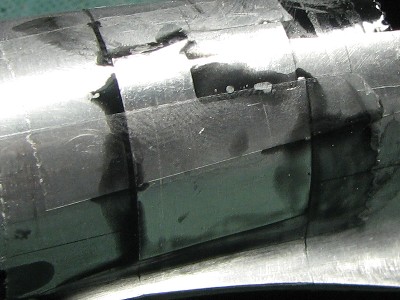

Next was port fuselage. The large dimple appeared. |

The panel was removed and the base was cleaned. |

The new panel was 0.3mm aluminum sheet to reduce the influence to blend into the surrounding surface. The sheet was cut and pressed carefully. |

The panel was glued and fixed with scotch tape. |

The surface was leveled off with the metal file and rough sanding paper attached to a stick. This repair work took almost one hour. I was so tired. |

|

|

The width near the cockpit was increased by 2mm and the fuselage outline became more accurate. |

The transition from the cowling and fuselage was like this. |

Please compare with the actual aircraft. |

The wing was combined. The colors of the front half and rear half were different due to different polishing. The front half was sanded with lower-grit sandpaper. |

|

|

Rivets and fasteners of cowling were finished. |

Fasteners of access panels were made with #3 (0.4mm) beading tool. |

|

|

Ha-109 engine was came from the kit. |

Plug cables were made from 0.3mm soldering wire. |

|

At first, I used the 0.1mm aluminum sheet, but it was too soft and hard to treat. So I decided to use the 0.2mm sheet. |

The 0.3mm plastic sheet was glued on the lower edge. |

The 0.3mm plastic sheet was glued on the canopy too. |

The rear half of the upper line was sanded to be straight. The lower line was also corrected. |

I checked the outline. Mmmm, OK! |

Canopy frames consisted of 6 parts. First, the front frame was glued. |

The portion of frames was painted black. And frames were glued with Black super glue. |

The shape of the frame was traced with tape and knife. |

The lower edge was to be adjusted afterwards. |

The round corner was cut out like this. |

After all the frames were glued they were sanded while the transparent areas were masked with tape. |

|

|

The correction of the canopy and fuselage outline resulted in this gap since the work wasn't completely accurate. |

The exact shape of the canopy should be narrower at the point of the arrow. But it needed heat pressing of the canopy. Would you accept that challenge? |

|

|

To form the lower frame, this mold was made from styrene sheet. |

The cross section of the front frame was adjusted with pliers. |

The outline was checked. It was a little tall due to the thickness of the plastic sheet. |

Frames were sanded. I took care of the edge on the front frames. |

The plastic sheet of lower edge was sanded and removed. |

Looks good! |

|

|

The horizontal and vertical stabilizers leading edges were sanded sharp. |

The panel was formed on another kit. |

The surface of the fillet was sanded. |

|

|

|

The oval lines were engraved and the gun exhausts were opened. |

Finally, the surface was polished with 600-grit sand-paper. |

|

|

Aluminum sheets were glued from the leading edge. |

Panels were glued one by one. |

The upper surface was sanded with a metal file followed by 320-grit sand-paper attached to a stick. |

|

I repeated the same on the lower sides. The front of the gear bay was difficult. |

On the wing tips I simply glued upper and lower pieces of aluminum sheet together. |

|

|

|

|

|